Magnetic forces are at the heart of countless modern technologies, and the battle between ferrite and neodymium magnets shapes the landscape of this invisible force. In this exploration, we'll delve into the characteristics, applications, and unique aspects of these two magnetic powerhouses.

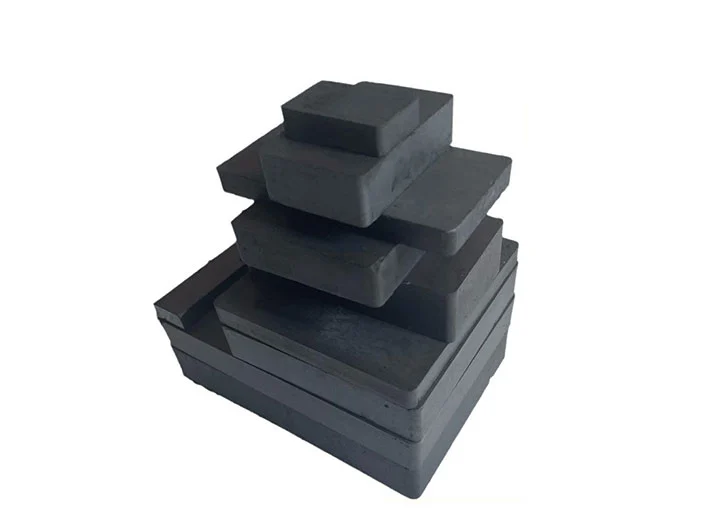

Ferrite Magnets: The Stalwarts

Composition and Characteristics

Ferrite magnets, also known as ceramic magnets, are crafted from a mix of iron oxide and barium or strontium carbonate. Their composition grants them a low-cost advantage, making them widely used in various applications.

Applications in Different Industries

Due to their affordability and moderate strength, ferrite magnets find their place in diverse industries. From speakers and refrigerator magnets to automotive applications, their versatility is unmatched.

Pros and Cons

While ferrite magnets are cost-effective and have a broad range of applications, their magnetic strength is comparatively lower than neodymium magnets. Understanding these pros and cons is crucial when considering them for specific uses. Tengye is one of the leading ferrite magnets manufacturers in China, types of ferrite magnets for sale.

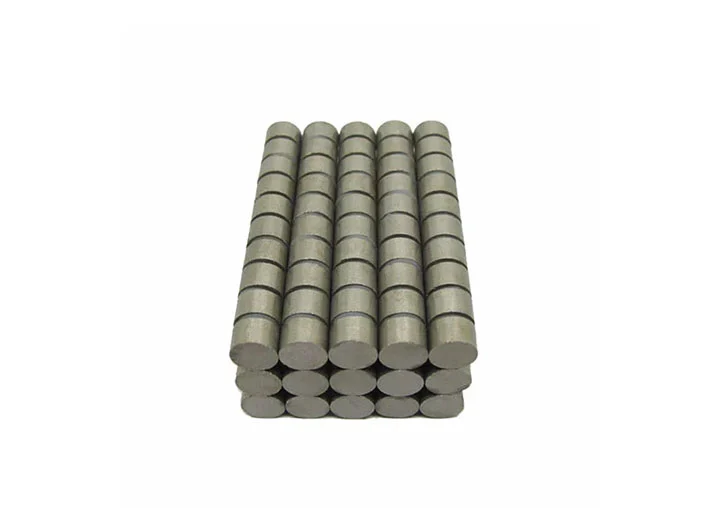

Neodymium Magnets: The Rising Stars

Unique Properties Setting Them Apart

Neodymium magnets, on the other hand, are a type of rare-earth magnet known for their exceptional strength. Composed of neodymium, iron, and boron, they have become the go-to choice in applications where high magnetic strength is paramount. Bulk neodymium magnets for sale from neodymium magnets company China.

Diverse Applications

From medical equipment to high-performance motors, neodymium magnets have carved a niche in applications demanding powerful magnetic forces. Their small size yet immense strength makes them indispensable in modern technology.

Advantages and Disadvantages

Neodymium magnets shine in terms of magnetic strength, but their higher cost and susceptibility to corrosion are factors to consider. Balancing these advantages and disadvantages ensures optimal use in specific scenarios.

Strength Showdown: Ferrite vs Neodymium

Magnetic Strength Comparison

In a head-to-head comparison, neodymium magnets undeniably come out on top in terms of magnetic strength. This strength translates to improved performance in various applications, especially those requiring compact and powerful magnets.

Real-world Scenarios Illustrating Their Differences

To grasp the significance of this strength disparity, let's consider scenarios such as speaker systems and magnetic closures, where neodymium's superior strength often results in more efficient and compact designs.

Impact on Performance in Applications

Understanding the magnetic strength's impact on performance is crucial for engineers, designers, and enthusiasts alike. The choice between ferrite and neodymium could mean the difference between an efficient, compact device and one that falls short of expectations.

Cost Considerations

Comparative Cost Analysis of Ferrite and Neodymium Magnets

While neodymium magnets outshine ferrite magnets in strength, they also come with a higher price tag. Evaluating the budget constraints of a project is essential, as sometimes the benefits of neodymium may not justify the additional cost.

Balancing Performance with Budget Constraints

Finding the delicate balance between performance and budget is an art. Depending on the application, opting for the more affordable ferrite magnet might be a strategic decision, especially when the increase in strength from neodymium isn't critical.

Durability and Environmental Factors

Resilience of Ferrite and Neodymium Magnets

Ferrite magnets boast robust durability and resist demagnetization, making them suitable for long-term use. Neodymium magnets, however, require protective coatings to prevent corrosion and maintain their strength over time.

Environmental Impact and Sustainability

As environmental consciousness rises, considering the ecological footprint of magnets is essential. Ferrite magnets, being less reliant on rare-earth materials, are often considered more environmentally friendly than their neodymium counterparts.

Applications in Electronics

Role of Ferrite Magnets in Electronic Devices

Ferrite magnets are integral to various electronic devices such as transformers and inductors. Their magnetic properties facilitate the efficient transfer of electrical energy, contributing to the functionality of these devices.

Neodymium Magnets' Contribution to Modern Technology

In contrast, neodymium magnets play a pivotal role in miniaturizing electronic components. From hard drives to headphones, their small size and potent magnetic field enable the creation of sleek and powerful devices.

Industrial Applications

Usage of Both Magnets in Industrial Settings

Both ferrite and neodymium magnets find applications in industrial settings. Ferrite magnets excel in applications where cost is a critical factor, while neodymium magnets dominate in industries where compact size and high strength are paramount.

Specific Industries Where One Excels Over the Other

Understanding the specific strengths of each magnet allows industries to make informed choices. For instance, neodymium magnets might be preferred in aerospace applications where minimizing weight is crucial.