Magnets play various important roles in the automotive industry, offering numerous applications and benefits. Here are some key applications of magnets in the automotive sector:

Electric Motors

Types of permanent magnets, typically made of neodymium, are widely used in electric motors in hybrid and electric vehicles. These magnets generate a magnetic field that interacts with the electrical currents, converting electrical energy into mechanical energy to drive the vehicle. Magnets contribute to the efficiency, power, and compactness of electric motors. Click here to contact permanent magnets manufacturers.

Alternators and Generators

Magnets are employed in alternators and generators to produce electricity for various vehicle systems and to charge the battery. These magnets are usually mounted on a rotor and rotate past copper coils, inducing an electric current. The magnetic field generated by the magnets is essential for the generation of electrical power.

Magnetic Sensors

Automotive systems rely on magnetic sensors for various functions. For instance, speed sensors use magnets to measure wheel rotation and provide input for systems like anti-lock braking, traction control, and speedometer readings. Magnetic sensors are also used for position sensing, such as in throttle position sensors and crankshaft position sensors.

ABS Systems

Anti-lock Braking Systems (ABS) utilize magnets and magnetic sensors to monitor wheel rotation and prevent wheel lock-up during braking. The magnetic sensors detect changes in wheel speed, enabling the ABS system to modulate brake pressure and prevent skidding, improving control and safety.

Fuel Efficiency

Magnets are utilized in devices such as fuel injectors and fuel pumps to enhance fuel efficiency. By using magnetic fields to influence fuel flow, these systems can improve atomization and combustion, resulting in better fuel efficiency and reduced emissions.

Suspension and Magnetic Ride Control

Some advanced suspension systems incorporate magnets to adjust the stiffness or damping characteristics of the suspension in real-time. Magnetic Ride Control (MRC) systems, for example, use magnetorheological fluid and electromagnetic coils to alter the viscosity and response of the suspension, providing improved handling and ride comfort.

Magnetic Door Latches

Many modern vehicles utilize magnetic door latches instead of traditional mechanical latches. These magnetic latches provide a secure and reliable closure, reducing noise, vibration, and wear compared to conventional latches.

Starter Motors

Magnets are used in starter motors to initiate the engine's combustion process. When an electrical current passes through the magnet, it generates a magnetic field that interacts with the engine's flywheel, enabling the engine to start.

These are just a few examples of the diverse applications of magnets in the automotive industry. Magnets contribute to the efficiency, performance, and functionality of various automotive systems, playing a crucial role in modern vehicles.

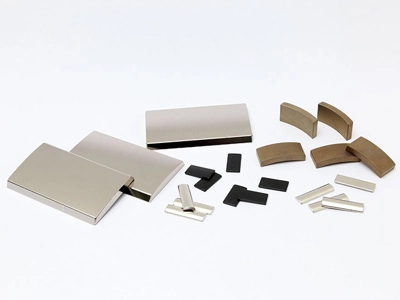

Learn more about neodymium arc magnets, micro magnets, wholesale neodymium magnets, wholesale segment magnet, etc.

Use Of Permanent Magnets In Electric And Hybrid Vehicle Motors

Permanent magnets play a crucial role in electric and hybrid vehicle motors, specifically in the form of permanent magnet synchronous motors (PMSMs) and brushless DC motors (BLDC):

Permanent Magnet Synchronous Motors (PMSMs):

PMSMs are widely used in electric and hybrid vehicles due to their high efficiency and power density. They consist of a rotor with permanent magnets and a stator with windings. The key role of permanent magnets in PMSMs is to generate a magnetic field that interacts with the stator windings, resulting in the conversion of electrical energy to mechanical energy.

The permanent magnets, typically made of neodymium, samarium-cobalt, or ferrite materials, are mounted on the rotor. When the stator windings are energized with alternating currents, the resulting magnetic field from the magnets and the stator windings creates a rotating magnetic field. This rotating field exerts torque on the rotor, causing it to rotate and drive the vehicle.

The use of permanent magnets in PMSMs enhances motor efficiency, power output, and overall performance. The strong magnetic field generated by the permanent magnets allows for a more compact motor design, improved torque density, and reduced energy losses.

Brushless DC Motors (BLDC):

BLDC motors, also known as electronically commutated motors, are another type of motor commonly found in electric and hybrid vehicles. These motors utilize permanent magnets to produce the magnetic field required for rotation.

In a BLDC motor, the permanent magnets are fixed on the rotor, while the stator contains multiple windings. Instead of using brushes and a commutator, like in brushed DC motors, BLDC motors employ electronic controllers to switch the currents in the stator windings at the appropriate times. This electronic commutation allows for more precise control and improved efficiency.

The permanent magnets in BLDC motors create a fixed magnetic field that interacts with the changing magnetic field produced by the stator windings. As the currents in the windings change, the magnetic field generated by the permanent magnets causes the rotor to rotate, generating mechanical power.

Similar to PMSMs, the use of permanent magnets in BLDC motors provides high power density, improved efficiency, and better control over motor performance.

In both PMSMs and BLDC motors, the quality and strength of the permanent magnets are crucial factors that impact motor performance. Advances in permanent magnet technology, particularly with the development of strong neodymium magnets, have significantly contributed to the efficiency and power output of electric and hybrid vehicle motors.