Rare earth magnets, also known as neodymium magnets or rare earth neodymium iron boron magnets, are a type of powerful permanent magnet made from rare earth elements. The term "rare earth" refers to the fact that these elements were once considered rare, but they are actually fairly abundant in the Earth's crust. Rare earth magnets are extremely strong for their size and have a wide range of industrial and consumer applications.

The two most common types of rare earth magnets are neodymium-iron-boron (NdFeB) magnets and samarium-cobalt (SmCo) magnets. Neodymium magnets are the more widely used and are the strongest type of permanent magnet available commercially.

Characteristics and uses of rare earth magnets:

Strength: Rare earth magnets are exceptionally strong, with high magnetic field strength. They are known for their high energy density and can generate strong magnetic fields relative to their size.

Applications: These magnets are used in a wide range of applications, including electric motors, generators, speakers, MRI machines, computer hard drives, magnetic locks, headphones, and more. They are also used in various industrial settings, such as in sensors, separators, and lifting equipment.

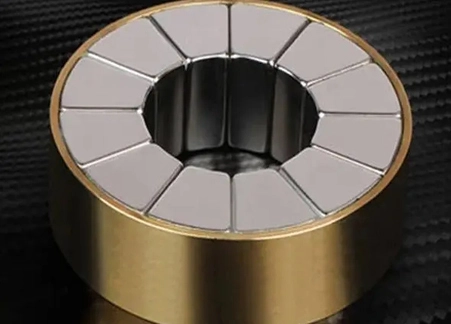

Sizes and Shapes: Rare earth magnets are available in various sizes and shapes, including discs, blocks, rings, and custom shapes. Their small size and high magnetic strength make them versatile for various designs.

Vulnerability to Demagnetization: Rare earth magnets are more susceptible to demagnetization than other types of magnets, so they need to be handled with care. They can lose their magnetism under certain conditions, such as exposure to high temperatures or strong external magnetic fields.

Composition: Neodymium magnets are made primarily from neodymium, iron, and boron, while samarium-cobalt magnets are composed of samarium, cobalt, and other elements.

Coatings: To protect against corrosion and wear, rare earth magnets are often coated with nickel, zinc, or other materials.

Safety Considerations: Due to their strength, rare earth magnets can be dangerous if mishandled. They can pinch or crush fingers, and larger magnets can pose serious risks if swallowed. Care should be taken when working with these magnets.

Types of Rare Earth Magnets

Certainly, here are the two main types of rare earth magnets:

Neodymium-Iron-Boron (NdFeB) Magnets:

Neodymium magnets are the most widely used and recognized type of rare earth magnets.

They are exceptionally strong and have the highest magnetic field strength among commercially available magnets.

Neodymium magnets are commonly used in various applications, including electric motors, generators, headphones, speakers, MRI machines, magnetic closures, and more.

They are composed primarily of neodymium, iron, and boron.

Samarium-Cobalt (SmCo) Magnets:

Samarium-cobalt magnets are another type of rare earth magnet, known for their high resistance to temperature and corrosion.

They are not as strong as neodymium magnets but still possess a high magnetic energy product.

SmCo magnets are used in applications where high-temperature stability is required, such as aerospace and military applications.

They are composed mainly of samarium and cobalt, with small amounts of other elements.

Both types of rare earth magnets offer unique properties and are utilized in different applications based on their characteristics. Neodymium magnets are more common due to their higher magnetic strength, while samarium-cobalt magnets are chosen when high-temperature performance and corrosion resistance are critical.

How are Rare Earth Magnets Made?

Rare earth magnets, specifically neodymium-iron-boron (NdFeB) magnets, are made through a complex manufacturing process that involves several key steps. Here's an overview of how rare earth magnets are typically produced:

Raw Material Extraction:

The process begins with the mining and extraction of raw materials. The primary raw materials for neodymium magnets are neodymium, iron, and boron. These materials are not mined as pure elements but are typically found in ore deposits.

Separation and Purification:

Alloy Formation:

Melting and Casting:

The alloy is melted in a furnace and cast into a desired shape, such as blocks, discs, or custom shapes, depending on the magnet's intended application.

Cooling and Annealing:

Grinding and Machining:

Coating:

Magnetization:

Inspection and Quality Control:

Packaging and Distribution:

Rare Earth Magnets applications

Electric Motors and Generators: Rare earth magnets are used in electric motors and generators to improve efficiency and reduce size and weight. They are commonly found in appliances, power tools, and automotive applications.

Speakers and Headphones: Neodymium magnets are used in high-quality speakers and headphones to produce clear and powerful sound. Their small size and strong magnetic field make them ideal for compact audio devices.

MRI Machines: Magnetic Resonance Imaging (MRI) machines use strong magnetic fields to generate detailed images of the body's internal structures. Rare earth magnets, especially neodymium, are used in the construction of MRI equipment.

Hard Disk Drives: Neodymium magnets are used in hard disk drives to position the read/write head accurately and maintain data storage integrity. They help to increase data storage capacity and data access speed.

Magnetic Separators: Rare earth magnets are employed in magnetic separators to remove ferrous contaminants from various materials, such as food products, minerals, and recycling streams.

Magnetic Couplings: They are used in applications where a hermetically sealed, non-contact torque transmission is required, such as in pumps and mixers in chemical and food processing industries.

Lifting Equipment: Large rare earth magnets are used in lifting equipment, such as magnetic cranes and hoists, to move heavy ferrous materials like steel plates and bars.

Magnetic Bearings: Rare earth magnets are used in magnetic bearing systems to provide frictionless and contactless support for rotating equipment, reducing mechanical wear and increasing efficiency.

Wind Turbines: Rare earth magnets are used in the generators of wind turbines to convert kinetic energy into electrical energy. Their compact size is advantageous in the design of these generators.

Sensors and Instrumentation: They are used in various sensor applications, such as in speed sensors, proximity sensors, and Hall effect sensors due to their sensitivity to magnetic fields.

Automotive Applications: Rare earth magnets can be found in various automotive components, including electric power steering systems, electric vehicle traction motors, and hybrid vehicle systems.

Aviation and Aerospace: Samarium-cobalt magnets are used in aerospace applications where extreme temperatures and high magnetic performance are necessary, such as in satellite systems and aircraft sensors.

Consumer Electronics: These magnets can be found in a wide range of consumer electronics, including smartphones, tablets, and cameras, where compact size and strong magnetism are advantageous.

Home Security Systems: Rare earth magnets are used in magnetic door and window sensors for home security systems.

Educational and Research Applications: They are often used in educational demonstrations and scientific experiments to illustrate magnetic principles.

How to choose the right magnet?

Choosing the right magnet for a specific application depends on various factors, including the intended use, environmental conditions, and performance requirements.

Define Your Application;

Magnet Type;

Size and Shape;

Magnetic Strength;

Temperature Tolerance;

Corrosion Resistance;

Safety Requirements;

Cost;

Testing and Verification;

Supplier Selection: